Cyclone filter separator

Cyclone separator is a single multistage equipment. At the inlet of primary separation section, the small-diameter hydrocyclone or blade uses the dynamic action of centrifugal force and gravity to remove liquid and solid particles. By removing most of the entrained liquid at this stage, the unique design increases the life of the high-efficiency condensing element and keeps the pressure drop accumulation to a minimum. This allows more time between changing elements, reducing operational costs and downtime.

Product advantage

By using the quick opening blind device, the replacement of combiner elements can be completed in the least time and work. The cyclone or vane type demister separators are completely maintenance free, cleanable, and do not replace or move components to cause shutdown.

Application area应用领域

·Ammonia and urea plants

·Desiccant bed protection

·Chemical plant

·Oil and mist removal

·Key gas treatment

·Gas regulation

·Molecular sieve protection

·Gas transmission / metering

·Power plant

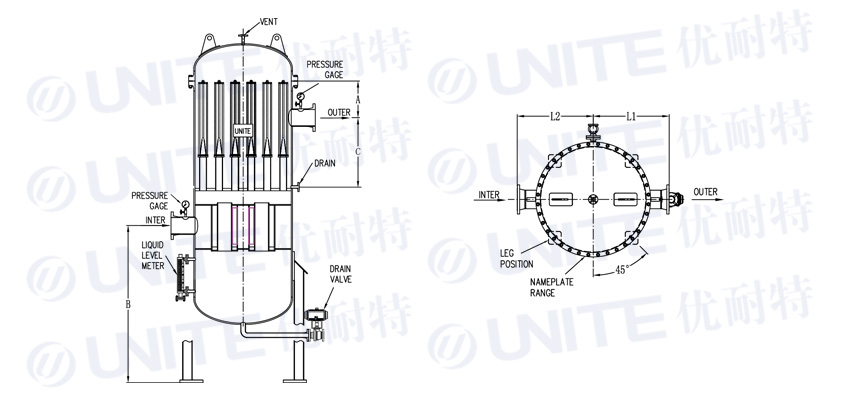

Operation principle

Cyclone tube

When the gas containing fog and solid enters the main separation section of the container, the entrained liquid and sold particles are affected by centrifugal force.

(a) the dirty gas enters the cyclone tube at two tangent lines.

(b) the shell forces the gas to form a cyclonic flow pattern. The centrifugal force throws the solid and liquid to the inner swirl pipe wall.

(c) solid and liquid particles are discharged into the wall of cyclone tube and gathered at the bottom.

(d) clean gas flows down and then up through the center annulus, from the top outlet.

Blade element

In the application without considering solid particles, the vane demister is the main separator.

(a) the contaminated gas entering the vane device enters the adjacent vertical pipes directly, in which each pipe makes the gas change several times rapidly in the direction.

(b) the inertia force caused by rapid direction change makes the liquid drop exert force on the impeller wall. The droplets agglomerate on the impeller wall.

(c) gravity, surface tension, and momentum drive condense the liquid into the impeller pocket. The liquid flows out of the pocket and accumulates in the liquid reservoir.

(d) clean gas is discharged from the tail of the blade set.

Brand-name products in Jiangsu," "National Customer Satisfaction Brand" and the honorary title of the winner.

- E-mail:unite@unitefilter.com

- Address:No. 24 all the way,industrial park,new area,Wuxi